Buyer Guide

Best Laser Engraver for All Materials: Complete Guide

IGOLDENLASER’s range of laser engraving machines is well-suited for users seeking versatility across different materials. Whether for personal projects or industrial applications, their machines provide reliable performance and high-quality results. When considering a purchase, evaluate specific needs such as material types, production volume, and precision requirements to select the best model.

Best Laser Engraver for All Materials

Finding the best laser engraver for all materials requires understanding the different laser technologies and their material compatibility. With significant advancements in the laser engraving industry, machines are becoming more powerful, offering more features, and providing better value for money. This comprehensive guide will help you choose the perfect laser engraver based on your material requirements and budget.

Understanding Laser Types for Different Materials

The key to finding the best laser engraver for all materials lies in understanding how different laser technologies interact with various substances. Each laser type excels with specific materials while having limitations with others.

CO2 Laser Engravers: The Versatile All-Rounder

CO2 laser engravers are often considered the best choice for working with multiple materials. The iGL 55W CO2 laser engraver can engrave and cut all acrylics, including clear acrylics, which is one of the benefits of a CO2 laser cutter.

Materials CO2 Lasers Excel At:

- Wood (all types including hardwood, softwood, plywood, MDF)

- Acrylic and plastic materials

- Paper and cardboard

- Leather and fabric

- Rubber materials

- Glass (surface engraving)

- Stone and ceramic (marking)

- Food materials (for decoration)

Limitations:

- Cannot engrave bare metals effectively

- Limited performance on reflective materials

Fiber Laser Engravers: Metal Specialists

While fiber lasers, CO2 lasers, and diode lasers can all be used to engrave metal, fiber lasers are ideal for production line applications.

Materials Fiber Lasers Excel At:

- All metals including steel, aluminum, brass, copper

- Anodized aluminum

- Painted metals

- Some plastics (dark colors)

- Ceramics and carbides

Limitations:

- Cannot cut or engrave wood, leather, or organic materials

- Limited effectiveness on transparent materials

Diode Laser Engravers: Affordable Versatility

Diode lasers are ideal for soft materials, perfect for engraving wood, leather, acrylic, and paper, offering solid durability and consistent results.

Materials Diode Lasers Handle:

- Wood (light engraving and cutting)

- Leather and fabric

- Paper and cardboard

- Dark plastics and acrylic

- Anodized aluminum (light marking)

Limitations:

- Lower power limits cutting thickness

- Cannot engrave bare metals effectively

- Slower processing speeds

UV Laser Engravers: Precision for Delicate Materials

UV lasers offer unique advantages for sensitive materials that require precise, heat-free processing.

Materials UV Lasers Excel At:

- Glass (subsurface engraving)

- Ceramics and porcelain

- Electronic components

- Delicate plastics

- Medical device materials

- Precious metals (minimal heat effect)

Top Laser Engraver Recommendations for All Materials

Best Overall: iGL CO2 Laser Engraver

If you’re picking a professional small business desktop laser engraver, the iGL is the go-to choice. Many materials can be engraved or cut perfectly, and it’s not just an all-rounder for acrylic.

Key Features:

- 55W CO2 laser for versatile material processing

- Autofocus capability for consistent results

- Dual cameras for precise positioning

- Class 1 laser safety rating

- Bluetooth connectivity for remote control

Material Compatibility: Excellent for wood, acrylic, leather, fabric, paper, rubber, and glass surface engraving.

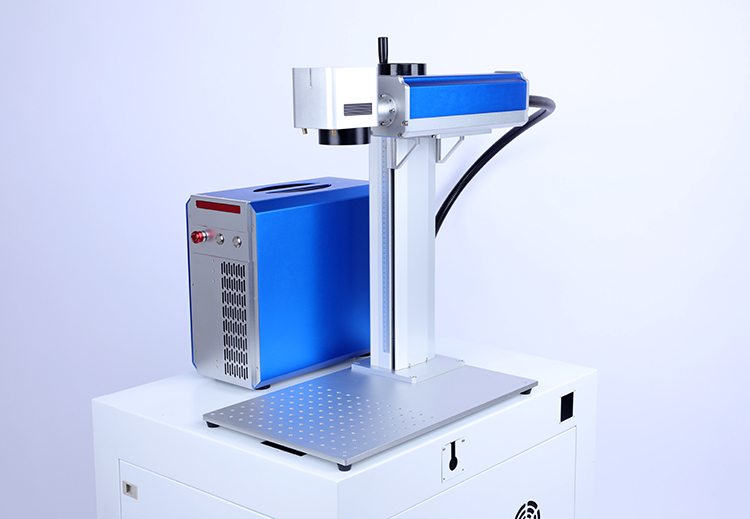

Best for Metal Work: Professional Fiber Laser Systems

For applications requiring metal engraving capabilities, dedicated fiber laser systems provide superior results for industrial and commercial applications.

Key Features:

- High-power fiber laser technology

- Precision marking on all metal types

- Fast processing speeds

- Minimal maintenance requirements

- Long-term durability

Best Budget Option: Entry-Level Diode Lasers

The 5W and 10W diode laser models are perfect for hobbyists and beginners who want to start engraving without a large upfront investment.

Advantages:

- Low initial cost

- Compact desktop design

- User-friendly operation

- Suitable for hobby applications

Best Portable Solution

The iGM is definitely the most amazing portable laser engraver. With 4000 mm/s engraving speed, iGM has become the fast-engraving portable laser engraving machine.

Choosing the Right Laser for Your Material Needs

Multi-Material Projects

For projects requiring work with diverse materials, consider a CO2 laser engraver as your primary machine. These systems offer the broadest material compatibility while maintaining excellent quality across different substrates.

Metal-Focused Applications

If you run a production line, you’ll need a fiber laser. If you have a small business or just want to do DIY projects as a beginner, a CO2 laser or a diode laser may be sufficient.

Budget Considerations

Entry-level diode lasers provide an affordable introduction to laser engraving with decent material compatibility for organic materials and light-duty applications.

Essential Features for Multi-Material Laser Engravers

Adjustable Power Settings

Variable power control allows optimization for different materials, from delicate papers requiring low power to thick woods needing maximum output.

Autofocus Capability

Automatic focusing ensures consistent results across varying material thicknesses without manual adjustments.

Safety Features

Class 1 laser safety ratings and enclosed cutting areas provide protection when working with diverse materials.

Software Compatibility

Advanced software supporting multiple file formats and material presets simplifies the transition between different projects and materials.

Material-Specific Tips and Best Practices

Working with Wood

- Use lower speeds for hardwoods

- Multiple light passes often produce better results than single heavy passes

- Ensure proper ventilation for smoke removal

Acrylic and Plastic Processing

- CO2 lasers provide the cleanest cuts and smoothest edges

- Use proper material supports to prevent warping

- Consider flame-polishing for crystal-clear edges

Metal Engraving Considerations

- Fiber lasers deliver permanent, high-contrast marks

- Surface preparation can improve engraving quality

- Consider anodized or coated metals for better contrast

Future-Proofing Your Investment

Expandable Systems

Consider laser engravers that offer upgrade paths, allowing you to increase power or add capabilities as your needs evolve.

Manufacturer Support

Choose established manufacturers with strong customer support, comprehensive warranties, and readily available replacement parts.

Software Updates

Systems with regular software updates ensure compatibility with new materials and improved processing capabilities.

Conclusion

The best laser engraver for all materials depends on your specific requirements, but CO2 laser systems currently offer the broadest material compatibility. Whether you’re in the industrial sector, running a small business, or pursuing your creative passion, selecting the right machine is crucial.

For maximum versatility, a quality CO2 laser engraver like the IGOLDENLASER provides excellent performance across the widest range of materials. For specialized applications requiring metal processing, dedicated fiber laser systems deliver superior results.

Consider starting with a CO2 system for general versatility, then adding specialized lasers as your material requirements expand. This approach provides the flexibility to handle virtually any material while optimizing quality and efficiency for specific applications.

Remember that the best laser engraver is one that matches your current needs while providing room for future growth and expansion into new materials and applications.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.