Laser Knowledge

Laser Rust Removal VS Sandblasting Machine Rust Removal

When it comes to rust removal, two popular methods are laser rust removal and sandblasting. Each technique has its advantages and disadvantages. Here’s a comparison to help you understand which method might be best for your needs.

Laser Rust Removal VS Sandblasting

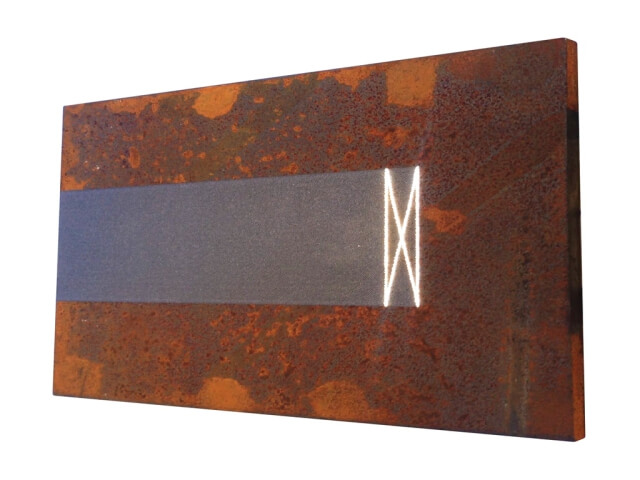

Laser rust removal mainly uses a laser beam to work on the workpiece with rust stains. High-frequency high-energy laser pulses irradiate the surface of the workpiece, and the coating layer can instantly absorb the focused laser energy, so that the oil stains, rust spots or coatings on the surface can be instantly Evaporation or peeling, a cleaning method that effectively removes surface attachments or surface coatings at high speed, and laser pulses with very short action time will not damage the metal substrate under appropriate parameters.

The rust removal of the sandblasting machine mainly uses compressed air as the power to form a high-speed jet beam and then spray it to the surface of the workpiece to be treated at a high speed, so that the surface of the workpiece can be changed.

Both laser derusting and sandblasting are mainly used for the treatment of various pollutants such as rust stains on some workpieces, but the efficiency and mode of action of the two are different. Laser derusting can be carried out directly during processing, while sandblasting It is necessary to remove the excess material on the surface of the workpiece to achieve a better rust removal effect. In contrast, the processing efficiency of laser rust removal is higher than that of sandblasting machine; secondly, the operation steps of sandblasting machine are a bit cumbersome, not to mention low efficiency, sometimes it may damage the workpiece, not clean, and cause environmental pollution, etc. and other phenomena, and laser rust removal is a green, non-destructive cleaning and low-cost cleaning processing method.

Laser rust removal does not require any chemicals, and the waste after rust removal is solid and harmless powder, which can completely solve the environmental pollution problem caused by chemical rust removal; and laser rust removal is a non-contact processing method, let alone worry about it. Damage or deformation to the workpiece, and the initial investment of the laser rust removal system is high, but it can be used stably for a long time, with a service life of up to 10 years, low operating cost, high speed, high efficiency, time saving, and can be quickly obtained. The return on investment, in the long run, is lower cost than the blast machine method.

Laser Rust Removal

Advantages

- Precision: Laser rust removal allows for targeted treatment of specific areas without affecting surrounding surfaces.

- Minimal Waste: This method generates less waste and does not require additional materials, making it more environmentally friendly.

- No Surface Damage: Lasers can remove rust without abrasive damage to the underlying material, preserving the integrity of the surface.

- Less Cleanup: The process produces minimal debris, reducing post-treatment cleanup efforts.

Disadvantages

- Initial Cost: The equipment can be expensive to purchase and maintain.

- Training Required: Operators need proper training to use the laser equipment effectively and safely.

- Slower for Large Areas: While precise, laser removal may take longer for extensive rust coverage compared to sandblasting.

Sandblasting

Advantages

- Speed: Sandblasting is generally faster for large surface areas, making it effective for extensive rust removal.

- Cost-Effective: The initial investment in sandblasting equipment is often lower than that of laser systems.

- Versatility: Sandblasting can be used on various surfaces and for different applications beyond rust removal, such as surface preparation.

Disadvantages

- Surface Damage: The abrasive nature of sandblasting can cause pitting and damage to softer materials.

- Waste Generation: It produces significant debris and dust, requiring more extensive cleanup and environmental considerations.

- Health Hazards: The process can create airborne particles that pose health risks, necessitating proper safety equipment.

Conclusion

Choosing between laser rust removal and sandblasting depends on your specific needs, budget, and the materials involved. For precision and minimal damage, laser rust removal is ideal. For larger areas and faster results, sandblasting may be the better option. Consider your project’s requirements carefully to make the best decision.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.