Laser Knowledge

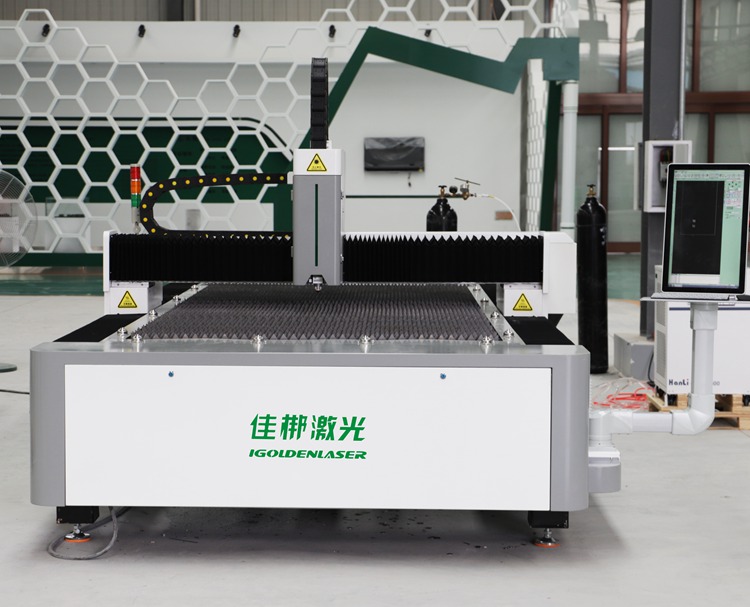

Best Stainless Steel Laser Cutting Machine for Sale

In the world of modern manufacturing, precision and efficiency are paramount. One technology that has revolutionized the industry is stainless steel laser cutting machines. These advanced machines utilize the power of lasers to cut through stainless steel sheets with incredible precision and speed. In this guest post, we will explore the numerous advantages of stainless steel laser cutting machines and their impact on the manufacturing sector.

Stainless steel laser cutting machine supplier will introduce you to the best stainless steel cutting machine in china. Before introducing, let’s understand some knowledge about laser cutting.

Stainless Steel Laser Cutting Machine

Stainless steel laser cutting machines excel at cutting complex designs and intricate patterns that would be difficult, if not impossible, to achieve with traditional cutting methods. This opens up endless possibilities for designers and engineers, allowing them to create innovative and visually striking products. Whether it’s decorative elements, logos, or custom shapes, laser cutting machines provide the flexibility to bring any design to life.

Stainless steel laser cutting machines have revolutionized the manufacturing industry with their precision, versatility, speed, and efficiency. From their unmatched precision to their ability to handle various materials, these machines offer numerous advantages that have transformed the way products are made. As technology continues to advance, stainless steel laser cutting machines will play an increasingly vital role in modern manufacturing, empowering businesses to stay competitive and meet the evolving needs of their customers.

Stainless steel laser cutting machines offer unrivaled precision when it comes to cutting complex shapes and intricate designs. The focused laser beam allows for accurate cuts, resulting in clean edges and smooth finishes. This level of precision is crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation can lead to costly errors.

Stainless steel laser cutting machines are highly versatile and can handle a wide range of applications. They can cut through various thicknesses of stainless steel sheets, from thin foils to thick plates, making them ideal for diverse manufacturing needs. Additionally, these machines can also handle other materials like aluminum, brass, and copper, further expanding their usability.

Stainless steel sheets can be expensive, and minimizing material waste is crucial for cost-effective manufacturing. Laser cutting machines optimize material usage by creating precise cuts and minimizing the kerf width (the width of the cut). This means that more parts can be produced from a single sheet, reducing material waste and saving money in the long run.

Compared to traditional cutting methods, stainless steel laser cutting machines offer significantly faster production rates. The laser technology enables rapid cutting speeds, reducing overall manufacturing time. This increased efficiency translates into higher productivity, shorter lead times, and improved customer satisfaction. Manufacturers can complete projects faster, meet tight deadlines, and take on more orders.

Features of Fiber Laser Cutting Machine for Stainless Steel

- Fiber lasers are preferred for cutting stainless steel due to their high energy efficiency and excellent beam quality. They provide a concentrated and powerful beam that can easily cut through stainless steel sheets of various thicknesses.

- The power output of the fiber laser source determines the cutting speed and thickness capacity of the machine. For cutting stainless steel, machines with higher power outputs are often preferred, especially for thicker materials.

- The cutting head of the laser machine should be designed to handle stainless steel efficiently. It should have features such as autofocus capabilities, nozzle cleaning systems, and high-pressure assist gases to optimize the cutting process and achieve clean, precise cuts.

- Fiber laser cutting machines offer high precision and accuracy, which is crucial when cutting stainless steel for applications where tight tolerances are required. Look for machines with advanced motion control systems and laser beam delivery systems to ensure precise cutting results.

- The worktable of the laser cutting machine should be designed to support stainless steel sheets securely during the cutting process. It should have features such as automatic material clamping systems and exchange tables to streamline the workflow and maximize productivity.

- Laser cutting machines should incorporate safety features to protect operators and prevent accidents. This may include enclosed cutting areas, safety interlocks, laser beam guards, and fume extraction systems to ensure safe operation in industrial environments.

- The machine’s control software should offer intuitive programming interfaces and nesting capabilities to optimize material usage and minimize scrap. It should also support CAD/CAM integration for seamless design-to-cut workflows.

Laser Stainless Steel Cutter Applications

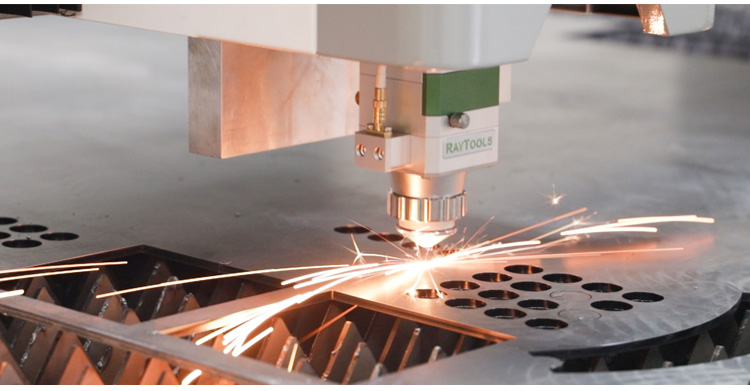

The stainless steel laser cutter uses a laser beam to cut through the stainless steel sheet or plate with high precision and accuracy.

Stainless steel laser cutter is mostly used in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

How Laser Cutting Works

Thermal processes involve rigorous mechanisms to execute precise results. Below are step-by-step details describing how laser cutting works.

A closed apparatus containing a laser-sensitive material is stimulated by electrical energy to produce a laser beam. The beam is reflected by mirrors within the apparatus and continuously bombarded until it surpasses the threshold limits, generating a monochromatic light with coherence. The concentrated beam is then directed to the desired location using mirrors or fiber optics and can be controlled through computer numerical control (CNC) for precision cutting. Usually, cutting begins from the edge, but if necessary, a high-pulsed laser beam can be used to create a hole for starting the cut in the middle of the material. The cutting process involves three stages: burning, melting, and vaporizing, which are used to slice materials such as metallic sheets, dies, or jewelry.

Stainless Steel Laser Cutting Machine Advantage

1. Cutting Speed: The cutting speed and quality depend on various factors, including the thickness of the material, the laser power, and the focusing lens.

2. Cutting range: Decide on fiber lasers or gas lasers as per priority. Generally, fiber lasers assure more coverage in sheet dimensions, but this is a limited process. Above the optimum values, the product quality begins to decline.

3. Edge quality: Appropriate adjustments in cutting speed, focal point, and assist gas pressure can result in improved edge quality. While cutting steel, mostly nitrogen is the choice as the assist gas.

4. Thermal effect: Lowering the pressure value helps in reducing the thermal effect on the sheet.

5. Moreover, higher temperatures can melt the material below the cutting edge.

6.Efficient Interface: These machines are now blessed with automatic adjustment of cutting and blade gap adjustment, which ensures accuracy. The interface is simple to use and also has a material library for the reference of the user.

Stainless Steel Laser Cutting Parameter

| Material | Thickness(mm) | Max. Speed(m/min) | Assisted Gas | Remarks |

| 2000w

Stainless Steel |

1 | 24-30 | Nitrogen | |

| 2 | 10-17 | |||

| 3 | 4-6.5 | |||

| 4 | 3-4.5 | |||

| 5 | 1.8-2.5 | |||

| 6 | 1.2-2.0 | |||

| 8 | 0.7-1 |

| Material | Thickness(mm) | Max. Speed(m/min) | Assisted Gas | Remarks |

| 3000w

Stainless Steel |

1 | 30-42 | Nitrogen | |

| 2 | 18-21 | |||

| 3 | 8-12 | |||

| 4 | 6-9 | |||

| 5 | 3-5 | |||

| 6 | 3-4.3 | |||

| 8 | 1.5-2 | |||

| 9 | 0.8-1 |

| Material | Thickness(mm) | Max. Speed(m/min) | Assisted Gas | Remarks |

| 4000w

Stainless Steel |

1 | 40-55 | Nitrogen | |

| 2 | 20-30 | |||

| 3 | 12-18 | |||

| 4 | 8-12 | |||

| 5 | 4-6.5 | |||

| 6 | 4.0-6.5 | |||

| 8 | 1.8-3 | |||

| 10 | 0.8-1.5 | |||

| 12 | 0.6-1 | |||

| 15 | 0.5-0.8 | |||

| 20 | 0.4-0.5 |

| Material | Thickness(mm) | Max. Speed(m/min) | Assisted Gas | Remarks |

| 6000w

Stainless Steel |

1 | 60–80 | Nitrogen | |

| 2 | 30–42 | |||

| 3 | 18–24 | |||

| 4 | 10–18 | |||

| 5 | 8–12 | |||

| 6 | 6–9 | |||

| 8 | 4–5 | |||

| 10 | 1.8–2.5 | |||

| 12 | 1.2–1.8 | |||

| 15 | 0.6–0.8 | |||

| 20 | 0.5–0.8 | |||

| 25 | 0.4–0.5 |

| Material | Thickness(mm) | Max. Speed(m/min) | Assisted Gas | Remarks |

| 8000w

Stainless Steel |

1 | 70–90 | Nitrogen | |

| 2 | 40–55 | |||

| 3 | 30–38 | |||

| 4 | 18–24 | |||

| 5 | 12–17 | |||

| 6 | 8–14 | |||

| 8 | 6–8 | |||

| 10 | 3–5 | |||

| 12 | 1.8–3 | |||

| 15 | 1.2–1.8 | |||

| 20 | 0.6–0.7 | |||

| 25 | 0.5–0.6 | |||

| 30 | 0.4–0.5 |

| Material | Thickness(mm) | Max. Speed(m/min) | Assisted Gas | Remarks |

| 10000w

Stainless Steel |

1 | 80–100 | Nitrogen | |

| 2 | 50–65 | |||

| 3 | 37–45 | |||

| 4 | 24–32 | |||

| 5 | 15–22 | |||

| 6 | 12–15 | |||

| 8 | 8.0–12.0 | |||

| 10 | 6.0–8.0 | |||

| 12 | 3.0–5.0 | |||

| 15 | 1.8–3.0 | |||

| 20 | 1.2–1.8 | |||

| 25 | 0.6–0.7 | |||

| 30 | 0.5–0.6 | |||

| 40 | 0.4–0.5 |

| Material | Thickness(mm) | Max. Speed(m/min) | Assisted Gas | Remarks |

| 12000w

Stainless Steel |

1 | 90–120 | Nitrogen | |

| 2 | 60-75 | |||

| 3 | 43–52 | |||

| 4 | 30–50 | |||

| 5 | 18–25 | |||

| 6 | 15–21 | |||

| 8 | 10–16 | |||

| 10 | 8.0–12 | |||

| 12 | 6.0–8.0 | |||

| 15 | 3.0–5.0 | |||

| 20 | 1.8–3.0 | |||

| 25 | 1.2–1.8 | |||

| 30 | 0.6–0.7 | |||

| 40 | 0.5–0.6 |

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.