Laser Knowledge

What is a Fiber Laser Cutting Machine?

After years of development, fiber laser cutting machines have greatly improved the production efficiency of various industries and are increasingly favored in many industries.

A fiber laser cutting machine is a device that uses laser technology for processing and production, adopting a non-contact processing method.

Compared with traditional methods, fiber laser cutting machines do not cause material deformation or damage and can provide fast and accurate processing services.

For this reason, more and more companies are choosing to invest in fiber laser cutting machines.

For many enterprises, purchasing a best fiber laser cutting machine for metal fabrication is a crucial decision.

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine uses a fiber laser generator as the light source, and the fiber laser is a new type of laser that has emerged and developed internationally in recent years.

A high-energy-density laser beam is focused on the surface of the workpiece, causing the ultra-fine focal irradiation area to melt and vaporize instantaneously, and the CNC mechanical system moves the light spot to realize automatic cutting.

Compared with traditional gas and solid-state lasers, fiber lasers have significant advantages and have become an important force in high-precision laser processing, laser radar systems, space technology, laser medicine, and other fields.

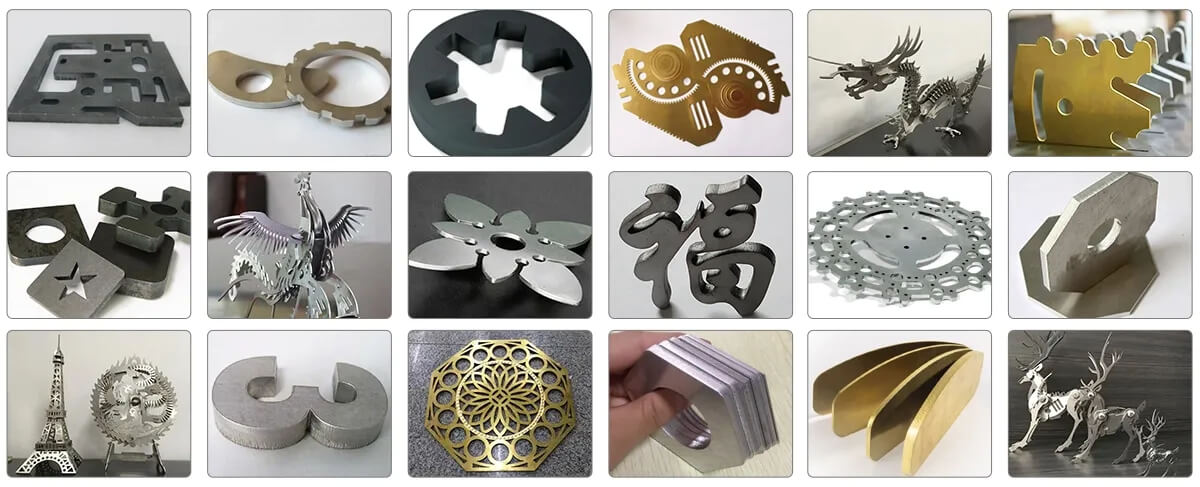

The best fiber laser cutting machine for metal fabrication can perform both plane cutting and bevel cutting, and the cutting edge is smooth and flat, making it an ideal choice for high-precision cutting of metal plates.

In addition, by adding a robotic arm, the machine can perform three-dimensional cutting, eliminating the need for a five-axis laser.

Compared with the traditional carbon dioxide laser cutting machine, the fiber laser cutting machine occupies less space, consumes less gas, and has a higher photoelectric conversion rate.

This is a new energy-efficient and environmentally friendly product and is regarded as one of the world’s leading technologies.

Laser Cutting Classification

Laser cutting is mainly divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting, and laser scribing and fracture control.

Laser Vaporization Cutting

A high-energy-density laser beam intensively heats the workpiece, causing its temperature to rise sharply to the boiling point of the material in a short time. At this time, the material begins to vaporize and form steam, which is ejected at a high speed, thus creating a notch in the material.

Due to the effect of the material’s heat of vaporization, laser vaporization cutting requires relatively large power and power density. This cutting method is mostly used for cutting thin metal materials as well as non-metal materials such as paper, cloth, wood, plastic, and rubber.

Laser Melting Cutting

In the process of laser melting cutting, the metal material is melted by the heat of the laser. Subsequently, a non-oxidizing gas (such as argon, helium, nitrogen, etc.) is injected through a nozzle coaxial with the beam, and the liquid metal is discharged by the strong pressure of the gas, thereby forming a notch.

Laser melting cutting does not require the metal to be completely vaporized, and the required energy is only one-tenth of that for vaporization cutting. It is mainly used for cutting materials that are not easily oxidized or active metals, such as stainless steel, titanium, aluminum, and their alloys.

Laser Oxygen Cutting

The principle of laser oxygen cutting is similar to that of oxyacetylene cutting. Laser is used as the preheating heat source, and an active gas such as oxygen is used as the cutting gas. The injected gas reacts oxidatively with the cutting metal, releasing a large amount of heat.

At the same time, the molten oxide and melt are blown out of the reaction zone, forming a notch in the metal.

Laser oxygen cutting requires only half the energy of melting cutting and is much faster than laser vaporization cutting and laser melting cutting. This method is mainly used for cutting easily oxidized metal materials such as carbon steel, titanium steel, and heat-treated steel.

Laser Scribing and Fracture Control

Laser scribing uses a high-energy-density laser to scan the surface of brittle materials, heating and evaporating the material to form small grooves, and then applying pressure to cause the brittle material to break along the grooves. Laser scribing commonly uses Q-switched lasers and CO₂ lasers.

Controlled fracture uses the steep temperature distribution generated by laser grooving to induce local thermal stress in brittle materials, causing the material to break along the small grooves.

Characteristics of Laser Cutting

Compared with other thermal cutting methods, laser cutting is known for its fast cutting speed and high quality.

The main advantages of laser cutting are as follows:

Excellent Cutting Quality

Laser cutting has better cutting quality due to the small laser spot, high energy density, and fast cutting speed.

- The incision of laser cutting is thin and narrow, the two sides of the cut are parallel and perpendicular to the surface, and the dimensional accuracy of the cut part can reach ±0.05mm.

- The cutting surface is smooth and beautiful, and the surface roughness is only a few tens of microns. In some cases, laser cutting can even be used as the final process, without the need for additional processing, and the parts can be directly put into use.

- The width of the heat-affected zone after laser cutting is very small, the material near the cut is hardly affected, the workpiece deformation is small, the cutting accuracy is high, the geometric shape of the cut is good, and the cross-sectional shape of the cut is a regular rectangle.

Table 1 compares the laser cutting, oxyacetylene cutting, and plasma cutting methods. The cutting material used is a 6.2mm-thick low-carbon steel plate.

Table 1 Comparison and calibration of laser cutting, oxyacetylene cutting and plasma cutting methods

| Cutting method | Slit width | Width of heat affected zone / mm | Slit shape | Cutting speed | Equipment cost |

| Laser cutting | 0.2-0.3 | 0.04-0.06 | Parallel | Fast | High |

| Oxyacetylene cutting | 0.9-1.2 | 0.6-1.2 | Relative parallel | Slow | Low |

| Plasma cutting | 3.0-4.0 | 0.5-1.0 | Wedge and inclined | Fast | Medium and high |

High Cutting Efficiency

The best fiber laser cutting machine for metal fabrication uses the transmission characteristics of the laser and is equipped with multiple CNC worktables to realize a fully CNC cutting process.

During operation, only by changing the CNC program can different shapes be cut, and both two-dimensional and three-dimensional cutting can be carried out.

Fast Cutting Speed

Using a 1200W laser, the cutting speed of a 2mm-thick low-carbon steel plate can reach 600cm/min, and the cutting speed of a 5mm-thick polypropylene resin plate can reach 1200cm/min.

During the cutting process, there is no need to clamp or fix the material, which saves time and reduces the need for tools and fixtures.

Non-contact Cutting

In laser cutting, the cutting torch does not contact the workpiece, so there is no tool wear.

To cut parts of different shapes, there is no need to change the “tool”, only the output parameters of the laser need to be adjusted.

In addition, the laser cutting process also has the advantages of low noise, small vibration, and no pollution.

Wide Range of Cuttable Materials

Compared with oxyacetylene and plasma cutting, laser cutting can cut a wider variety of materials, including metals, non-metals, metal matrix composites, non-metal matrix composites, leather, wood, and fibers.

However, due to the different thermophysical properties and laser absorption rates of these materials, their laser cutting adaptability also varies.

Disadvantages

Limited by the laser power and equipment size, laser cutting can only cut medium and small thickness plates and tubes.

In addition, as the thickness of the workpiece increases, the cutting speed will decrease significantly. The cost of laser cutting equipment is high, and the initial investment is large.

Laser Cutting Machines Application

A laser cutting machine focuses the emitted laser into a high-power laser beam through an optical path system.

Subsequently, the laser beam heats the surface of the workpiece to the melting point or boiling point. At the same time, the high-pressure gas coaxial with the beam removes the melted or evaporated metal.

By adjusting the relative position of the beam and the workpiece, the material is finally cut into the desired shape. The best fiber laser cutting machine for metal fabrication have high material compatibility.

Structural Steel

Better results can be obtained by cutting with oxygen. When oxygen is used as the processing gas, slight oxidation will occur on the cutting edge.

For plates with a thickness of no more than 4 mm, nitrogen can be used as the processing gas for high-pressure cutting, which can prevent the cutting edge from oxidizing.

For plates with a thickness of more than 10 mm, using a special laser plate and applying oil to the surface of the workpiece during the processing will achieve good results.

Stainless Steel

If the degree of oxidation of the cutting end face is within an acceptable range, oxygen can be used. Using nitrogen can make the cutting edge non-oxidized and burr-free, without the need for other treatments.

Applying a layer of oil on the surface of the plate can enhance the perforation effect without affecting the processing quality.

Aluminum

Although aluminum has a high reflectivity and thermal conductivity, depending on the alloy type and the laser power, aluminum with a thickness of less than 6 mm can still be cut. When cutting with oxygen, the cutting surface will be rough and hard.

However, when cutting with nitrogen, the cutting surface will be smoother. Pure aluminum is difficult to cut due to its high purity, and a “reflection absorption” device must be installed for cutting; otherwise, the reflection will damage the optical elements.

Titanium

Titanium plate cutting uses argon and nitrogen as the processing gases, and other parameters can refer to nickel-chromium steel cutting.

Copper and Brass

Both brass and copper have high reflectivity and excellent thermal conductivity. Brass with a thickness of less than 1 mm can be cut with nitrogen, and copper with a thickness of less than 2 mm can be cut with oxygen as the processing gas.

However, brass and copper can only be cut when a “reflection absorption” device is installed on the system; otherwise, the reflection will damage the optical elements.

How Does a Fiber Laser Cutting Machine Work

Laser Cutting Principle

Laser cutting uses a highly focused intense laser beam to irradiate the workpiece, causing the material to rapidly melt, vaporize, ablate, or reach a burnout state. Then, the molten material is blown away by a high-speed gas flow coaxial with the beam, thereby realizing the cutting of the workpiece. Laser cutting belongs to a thermal cutting method.

The CNC mechanical system is responsible for moving the irradiation position of the laser point, so that a narrow gap is continuously formed in the hole, thereby realizing automatic cutting.

Advantages of Fiber Laser Cutting Machines over CO₂ Laser Cutting Machines

Best fiber laser cutting machine for metal fabrication have multiple advantages, as follows:

- Excellent Beam Quality – Smaller focus, finer cutting lines, higher work efficiency, and better processing quality.

- Extremely Fast Cutting Speed – Its cutting speed is twice that of a CO₂ laser cutting machine of the same power.

- High Stability – The machine uses world-class imported fiber lasers, with stable and reliable performance, and the service life of key components can reach more than 100,000 hours.

- High Electro-optical Conversion Efficiency – The photoelectric conversion efficiency of the fiber laser cutting machine is about 30%, three times that of the CO₂ laser cutting machine, making it more energy-efficient and environmentally friendly.

- Very Low Operating Cost – The power consumption of the machine is only 20% to 30% of that of similar CO₂ laser cutting machines.

- Extremely Low Maintenance Cost – The machine does not require laser working gas and uses fiber transmission without a reflector, greatly saving maintenance costs.

- Convenient Operation and Maintenance – Fiber transmission, no need to adjust the optical path.

- Superior Flexible Light Guide Effect – Small in size and compact in structure, easily meeting the needs of flexible processing.

However, compared with carbon dioxide laser cutting machines, the cutting range of fiber lasers is relatively narrow. Due to the wavelength, it can only cut metal materials, and non-metal materials are not easily absorbed, thus limiting its cutting range.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.