Laser Knowledge

Laser Car Cleaning: The Future of Automotive Detailing

As the automotive industry continues to modernize, workshops and detailing shops are searching for cleaner, faster, and more efficient surface treatment methods. Laser car cleaning, once seen as a high-tech industrial process, is now rapidly becoming the preferred solution for car repair, restoration, and maintenance. In 2025, laser technology offers unparalleled precision and eco-friendly benefits, making it one of the most advanced techniques available for automotive detailing.

What Is Laser Car Cleaning?

Definition and Core Principle

Laser car cleaning—also known as laser rust removal or laser surface treatment—uses high-energy laser beams to remove rust, paint, oil, dirt, carbon deposits, and oxidation from car surfaces. The laser’s energy instantly vaporizes the contaminants without damaging the underlying metal.

How Laser Removes Rust and Contaminants

When the laser beam hits a dirty or oxidized surface, it heats the contamination layer and breaks its molecular bond. The material evaporates or peels off, leaving behind a clean, smooth surface ideal for repainting or further processing.

Types of Laser Cleaning Technologies

-

Pulsed Laser Cleaning – Suitable for delicate components.

-

Continuous Laser Cleaning – Faster and more powerful, ideal for automotive rust removal.

-

Wobble Laser Cleaning Head – Offers wider scanning patterns and higher efficiency (used in iGOLDENCNC Double Wobble Continuous Laser Cleaning Machine).

Laser Cleaning Car Parts

Rust Removal

Laser cleaning efficiently eliminates rust from various metals, restoring the original metallic surface color. It provides a superior alternative to traditional methods such as chemical cleaning, sandblasting, shot blasting, and mechanical grinding.

Oxide Layer Removal

Lasers can precisely remove oxide layers with controlled thickness, ensuring non-destructive cleaning. This makes it an ideal replacement for chemical treatments and mechanical abrasion.

Oil and Grease Removal

Laser degreasing is widely used in automotive manufacturing, electronics, and machining industries. It ensures efficient and precise oil removal, leaving surfaces clean and improving product quality as well as subsequent processing results.

Coating Removal

Laser cleaning effectively strips coatings from galvanized or aluminized sheets, significantly enhancing welding quality. It enables efficient, selective, and even inline coating removal.

Paint Removal

Extensively applied in aerospace, automotive manufacturing, rail transportation, and even cultural heritage restoration, laser paint removal efficiently strips paint without damaging the substrate. It is eco-friendly and safe, while also preparing surfaces for anti-corrosion treatment, welding, or refurbishment.

Laser Cleaning for Automotive Maintenance

Laser cleaning is widely used in the maintenance of brake discs, engine components, transmission systems, and other automotive parts. It efficiently removes rust, oil, and carbon deposits while avoiding chemical corrosion and mechanical wear, extending component lifespan and improving maintenance efficiency and quality.

Brake System Maintenance

Laser cleaning effectively removes coatings, rust, and oil from brake discs and pads without chemical solvents or manual grinding. This protects the parts, enhances braking performance, and ensures safety.

Engine Component Cleaning

During engine manufacturing, laser cleaning removes oil, rust, and other contaminants from critical components such as cylinder blocks and crankshafts. It ensures cleanliness and stable performance, reaching even tight gaps and corners for comprehensive cleaning.

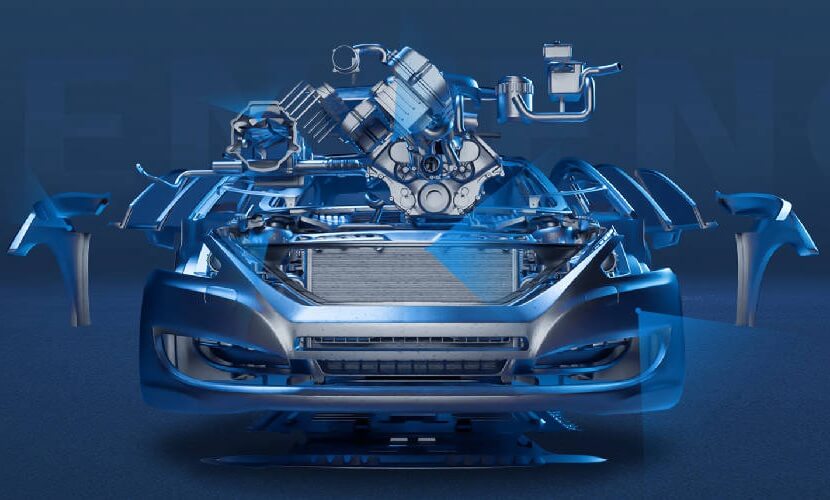

Body Frame Cleaning

Prior to welding, automotive body frames require removal of oxide layers and surface rust to ensure welding quality and structural strength. Laser cleaning completes this task quickly and efficiently, boosting production efficiency.

Wheel Rim Cleaning

Wheel rims accumulate brake dust and oil over time, affecting appearance and heat dissipation. Laser cleaning thoroughly removes these contaminants, restoring the metallic shine without causing any surface damage.

Car Parts Production and Assembly Processes

In the production and assembly of aluminum automotive bodies and components, laser cleaning is used for surface pre-treatment before welding—removing oxide layers and oil contaminants—and for post-weld residue removal. This ensures weld quality and improves overall assembly precision and reliability.

Body Repair

During automotive painting or refurbishment, laser cleaning quickly removes old paint layers, rust, or contaminants, providing an ideal surface for new coatings. This minimizes paint defects and enhances coating quality.

Post-Weld Treatment

Post-weld cleaning facilitates inspection and detection of welding defects, allowing surface flaws to be identified, removed, or repaired, thereby ensuring product quality.

Pulse Laser Cleaning for Car Engine

Pulse laser cleaning machines emit short laser pulses with high peak power, causing surface contaminants or coatings to vaporize or peel off instantly without damaging the substrate. Key characteristics include highly concentrated energy and extremely short interaction time, typically in the nanosecond to microsecond range, with adjustable frequency.

Continuous Laser Cleaning Machine

Continuous laser cleaning machines emit a steady laser beam, delivering constant energy to the surface. This heats, vaporizes, or chemically reacts with contaminants to achieve cleaning. The core feature is stable, continuous energy output.

Pulse laser cleaning achieves “cold ablation” through high peak power and short pulses, minimizing the heat-affected zone. Continuous laser cleaning relies on stable, continuous energy for efficient cleaning, but heat accumulation is more significant. For the same material and contamination, pulse lasers are more effective at removing stubborn deposits like oxide layers and welding slag, while continuous lasers are more efficient for cleaning large, flat surfaces. Engine cleaning in automotive applications typically uses pulse laser systems.

The Best Backpack Pulsed Laser Cleaning Machine

This portable pulsed laser cleaning machine combines ease of use with all the advantages of laser cleaning. Handheld laser cleaning systems are becoming increasingly popular. Compared to traditional chemical cleaning, mechanical grinding, or sandblasting, laser cleaning offers significant benefits: environmentally friendly, consumable-free, high cleaning precision, minimal substrate damage, and selective removal of contaminants.

Portable laser cleaning systems are particularly effective for complex-shaped workpieces, localized fine cleaning, and on-site maintenance, providing greater flexibility, operational freedom, and significantly improving efficiency and versatility.

Handheld Pulsed Laser Cleaning Machine

This entry-level, compact, lightweight, and easy-to-use solution is ideal for cleaning and surface treatment. Its non-contact system makes it especially suitable for industrial parts cleaning, mold cleaning, weld cleaning, and precision workshop maintenance.

Flexible Operation: Can be handheld, shoulder-mounted, or fixed; suitable for indoor and outdoor use.

Portable Power Supply: Supports external batteries for outdoor or mobile applications.

Lightweight and Compact: Laser head weighs only 650 g, making it easy to handle and operate.

Why Laser Cleaning Is Transforming Automotive Detailing

Non-Contact and Damage-Free

Laser cleaning does not physically touch the surface, so there is no risk of scratching, grinding marks, or surface deformation.

No Chemicals, No Consumables

Unlike chemical cleaning, laser cleaning produces no wastewater, no chemical smell, and no secondary pollution.

High Precision for Complex Auto Parts

Laser beams can reach tight corners, small screws, and complex engine components without dismantling the entire structure.

Faster Than Sandblasting

Continuous laser cleaning can remove rust 3–5 times faster than traditional sandblasting solutions.

Eco-Friendly and Workshop-Friendly

Laser cleaning only requires electricity. No abrasives and no toxic liquids means a cleaner and safer environment for workers.

Laser Cleaning vs Traditional Car Cleaning Methods

Laser Cleaning vs Sandblasting

| Laser Cleaning | Sandblasting |

|---|---|

| No surface damage | Causes scratches and pitting |

| No abrasives | Requires sand and disposal |

| Low noise | Very noisy |

| Precise | Difficult to control |

Laser Cleaning vs Chemicals

Laser is safer, cleaner, and environmentally friendly—no toxic liquids, no corrosion risks.

Laser Cleaning vs Manual Grinding

Manual grinding is slow, inconsistent, and risks damaging the base material.

Cost Comparison

Though the initial investment for a laser cleaning machine is higher, the long-term operational cost is nearly zero: only electricity is required.

Who Can Benefit From Laser Car Cleaning?

Auto Repair Workshops

Faster repair times mean higher customer turnover.

Car Detailing Shops

Laser cleaning becomes a premium service.

Classic Car Restorers

No risk of damaging valuable vintage components.

Automotive Manufacturers

Used for welding pre-treatment and production line cleaning.

Conclusion

Laser car cleaning represents a paradigm shift in automotive maintenance and restoration technology. The combination of precision, speed, environmental benefits, and superior results makes laser cleaning increasingly essential for professional automotive operations. While initial investment remains significant, the long-term advantages in efficiency, quality, and sustainability justify adoption for serious automotive businesses.

As technology matures and costs decrease, laser cleaning will likely become standard equipment in collision repair centers, restoration shops, and automotive manufacturing facilities worldwide. Early adopters gain competitive advantages through superior service quality, faster turnaround times, and enhanced environmental credentials that appeal to increasingly conscious consumers.

For automotive professionals committed to excellence and sustainability, laser cleaning technology offers a clear path forward in an evolving industry landscape.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.